What Is Valve

In an environment where the human population is increasing day by day in the changing world conditions, the agriculture sector is one of the most important areas for life.

In order for humanity to continue its life in a healthy way, it is the most important tool in which liquid chemical and organic fertilizers, which are effective in the growth of these products, are offered to the consumer, and as a result of the reactions caused by organic and chemical substances in plastic bottles and drums, it eliminates the effects such as swelling and explosion. throwing out the production of fluid supplying air to remove the vent cover is the first company in Turkey since 2006, producing with local and national resources. Our most important priority is to ensure customer satisfaction with a highly competitive and quality product portfolio in the national and international markets.

Packaging Vents

When containers filled with active formulations are not properly ventilated, inflated or collapsed containers can have serious consequences such as misaligned pallets, broken labels and leaks. The risk is greater when containers are stored, transported or distributed. Containers containing industrial chemicals and cleaners, agricultural products, household chemicals and cleaners can be extremely harmful to both users and the environment if not properly ventilated.

Metkap's valves minimize these risks:

Change of Appeal

Altitude changes during transportation cause pressure differences between the inside and outside of the package. Increasing altitude creates excessive pressure in the container, causing bloating. Falling altitude creates low pressure and causes collapse. Sudden or extreme altitude changes accelerate these deformations.

Dispensing Liquids

Dispensing liquids creates low pressure in the container. If this imbalance is not resolved, the container may collapse. Chemicals must breathe. Containers of agrochemicals such as liquid fertilizers and pesticides, whose natural variations cause fermentation and gas release at varying rates, need to be ventilated. Containers without proper ventilation holes may collapse, swell or leak when subjected to changes in altitude or temperature. Labels on containers may deteriorate and consequently important safety information may become potentially unreadable. Consumers may be exposed to leaking chemicals. Manufacturers may be in a difficult situation due to loss of efficiency and dissatisfied customers. The valves produced by Metkap minimize these risks even for chemical formulations with the highest concentration.

Why Valve?

Because the valve is a safe way to eliminate pressure differences that will cause liquid containers to deform, leak or explode.

For manufacturers, such defects can reduce productivity and efficiency in storage. It also damages the brand image when defective goods are returned or not sold at all.

Throughout the entire supply chain, leaks pose major risks and environmental hazards to end users, as well as costly cleaning processes.

The valves produced by Metkap minimize all these risks. The valve constantly and safely equalizes pressures to minimize the possibility of leakage and to preserve the integrity of the containers and their contents.

Container Gas Release or Consumption

Some active ingredients release gases in the container. If these gases cannot escape, the container will inflate, leak or even explode. Other active ingredients consume or scavenge oxygen, creating low pressure that can cause the container to collapse.

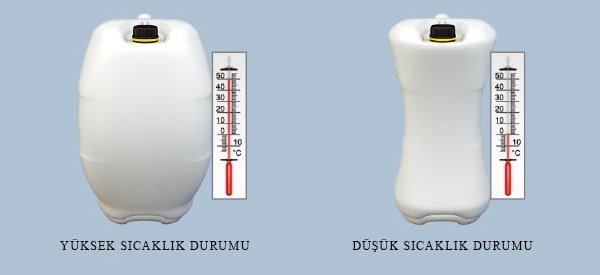

Temperature change

Temperature changes or exposure to different climates can also deform containers. Rising temperatures expand the gas in the headspace of the container and accelerate the decomposition of reactive chemicals that can cause excessive pressures and bloating. Falling temperatures can cause low pressures and collapse. Sudden or extreme temperature changes accelerate these deformations.

Foam Gasket and Capsule Vents

Standard Foam Seal and Capsule Valves provide security in the packaging of various products from household chemicals to liquid fertilizers and pesticides.

Foam Gasket Vents

Foam gasket and capsule valves, produced with the most advanced membrane technology, prevent container deformation and leakage. Maintains the integrity of the packaging during the storage and transportation of hazardous or aggressive chemicals, agrochemicals, industrial cleaners or household chemicals. Provides air flow even after contact with the most aggressive liquids. Resists leakage during transportation and use of aggressive, viscous or low surface tension liquids that disrupt the ventilation holes. Thanks to the Foam Seal Valves produced by Metkap, you can be more assured of the safety of dangerous, high viscosity or low surface tension formulations throughout the entire supply chain.